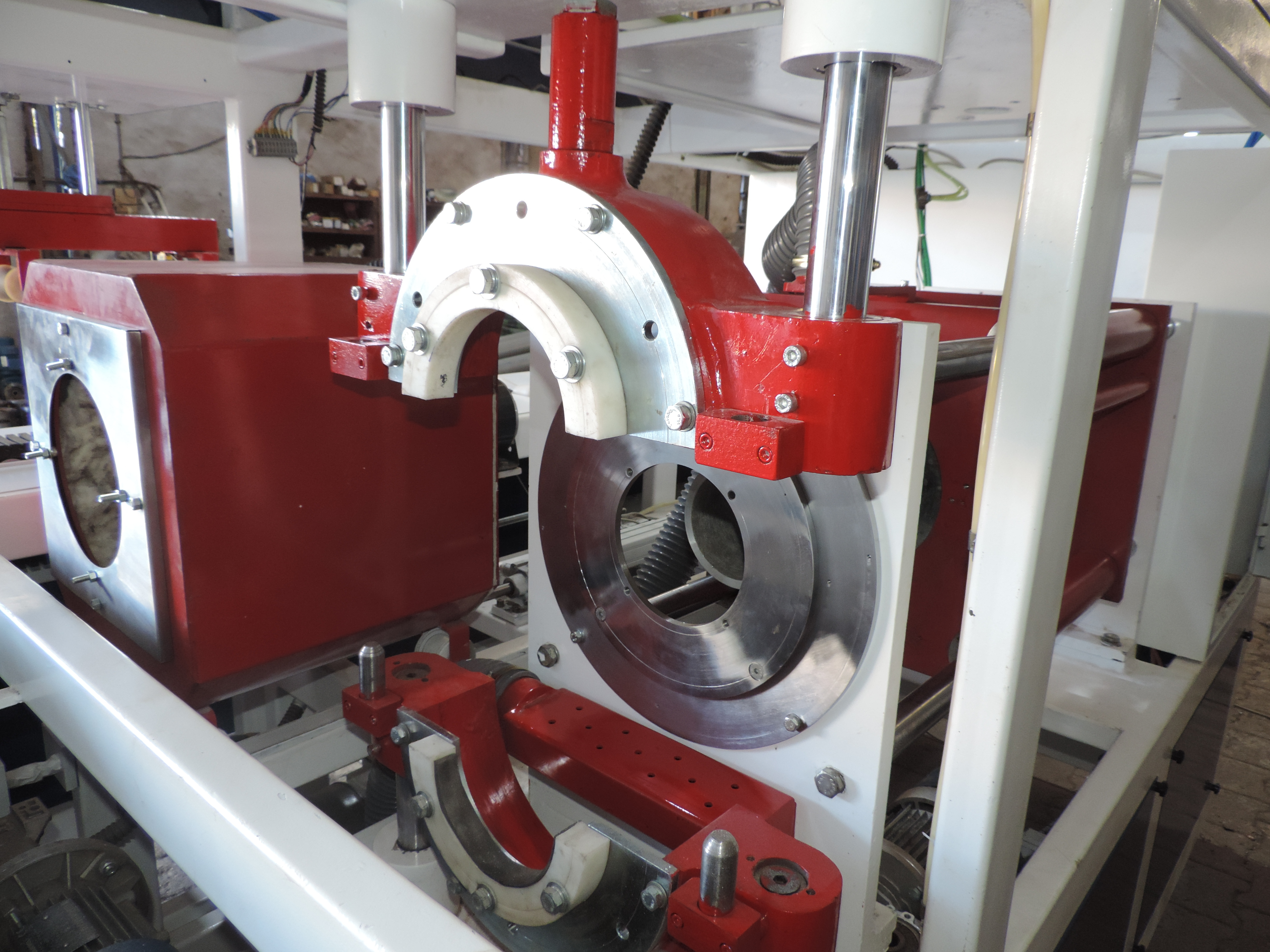

PVC Pipe Belling Machine

PVC Pipe Belling Machine Specification

- Bend Radius

- Adjustable

- Type

- PVC Pipe Belling Machine

- Material

- Mild Steel & Stainless Steel

- Capacity

- 50-200 mm pipe diameter

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Servo Motor

- Power

- 5 kW

- Weight (kg)

- 850

- Dimension (L*W*H)

- 3500 x 800 x 1450 mm

- Color

- Industrial Blue

PVC Pipe Belling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Payment Terms

- Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- Unit

- Delivery Time

- 5 Week

- Packaging Details

- As per Requirement

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- All India

About PVC Pipe Belling Machine

We, C and our Machinery Pvt. Ltd. Where Technology combineswith engineering brillianceto give the cuttingedge to the Plastic Processing equipments.

Fully Automatic Pneumatically operated smooth socket PVC Pipe end belling machine from 63mm to 200 mm with one forming station of Solid Steel mandrel & Single stage of Infrared heating of PVC pipes & External Air cooling , Monogram Embossing & Automatic Ejection .

Single Machine is Suitable for Solvent cement Joint, SWR Joint & Ring Fit (RR) Joints.Changing Mode for variant is by only selector switch only. Balance all will be fully Automatic.

PVC Pipe Belling Machine is applicable for solvent cement joint, SWR joint and many others. The balance it makes is fully automatic. The said product is accessible with easy changing tool system. Infrared heater is provided in the heating chamber so as to enable a suitable Insulation. PVC Pipe Belling Machine allows for easy movement on account of its pneumatic system. The easy operation process and PLC controls are provided to ensure outstanding performance.

TECHNICAL SPECIFICATION

- Easy & Quick Changing Tool System.

- Digital Temp. Controller with Sensor for heating system.

- Infrared Heater s heating chamber (inside SS) with suitable Insulation.

- Forced Air Cooling to cool pipe .

- Hard Chrome Plated Mandrels.

- High Quality Standard make Pneumatic Cylinder & Valves.

- Pipe Movement through Pneumatic system for up to 6 meter long PVC Pipes

- On line and off line mode will useful for using machine in both way.

- Power full Pipe ejection system after socketing.

- Easy operation process with digital display and alarm Indication.

- PLC Controlled Machine with Data Storage Facility.

- Universal Machine for Solvent Cement Joint, SWR Joint &

- Elastomeric Ring Socket for Dia 63 to 200 mm

Advanced Heating and Cooling System

Equipped with an infrared heater for uniform pipe warming and a water spray cooling system for quick stabilization, this belling machine delivers precise, consistent results. The integrated technologies ensure optimal socket formation and minimal cycle times, supporting increased productivity for your pipe manufacturing operations.

User-Friendly and Safe Operation

A sophisticated PLC control system and touch-screen interface make operation straightforward, even for new users. Enhanced safety features such as automatic emergency stop and overheat protection offer peace of mind, while the centralized manual lubrication system simplifies maintenance.

Flexible and High-Capacity Production

Supporting pipe diameters from 50 mm to 200 mm and lengths up to 6 meters, this machine is highly adaptable. With production speeds of up to 4 cycles per minute, it meets the demands of both small and large-scale manufacturing. Onsite installation and training services are available across India.

FAQs of PVC Pipe Belling Machine:

Q: How does the infrared heating system benefit the belling process for PVC and UPVC pipes?

A: The infrared heating system provides uniform and controlled heating, allowing pipe ends to reach the optimal temperature for belling without causing material stress or deformation, resulting in consistently precise socket and rubber ring joints.Q: What is the process for switching between plain, socket, and rubber ring belling types?

A: Switching between belling types involves selecting the desired mode on the touch screen interface and, if necessary, changing the forming tools. The PLC system automates most adjustments for efficient transitions between belling styles.Q: When should the centralized manual lubrication system be serviced?

A: The centralized manual lubrication system should be checked and re-filled regularly, depending on the machines operation frequency. Its recommended to inspect it daily before use and lubricate all key points as per the manufacturers maintenance schedule.Q: Where can installation and training services be accessed for this machine?

A: Onsite installation and operator training are offered by the manufacturer or distributor throughout India. These services ensure correct setup, optimal machine performance, and operator proficiency.Q: What safety features protect operators while using this PVC Pipe Belling Machine?

A: The machine includes automatic emergency stop and overheat protection systems, which immediately halt operation if unsafe conditions are detected, thereby preventing accidents and equipment damage.Q: How can I maximize the machines production speed while ensuring quality?

A: You can maximize production by selecting the appropriate heating and cooling parameters for your specific pipe size, regularly maintaining the machine, and utilizing the touch-screen control for precise settings. The PLC system ensures optimal cycle timing for both efficiency and consistency.Q: What benefits does PLC-controlled automation offer over manual pipe belling?

A: PLC-controlled automation increases consistency, reduces human error, improves production speed, and allows for customizable cycle settings. This results in higher-quality belling, reduced downtime, and easier operation with less specialized training required for workers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS