Powder Conveying Systems

Powder Conveying Systems Specification

- Bend Radius

- 900 mm

- Type

- Powder Conveying Systems

- Material

- Stainless Steel

- Capacity

- 200-500 kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Screw Diameter

- 100-150 mm

- Power

- 4 kW

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 2650 x 960 x 1300 mm

- Color

- Grey

Powder Conveying Systems Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Unit

- Delivery Time

- 1 Week

- Packaging Details

- As per Requirement

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- All India

About Powder Conveying Systems

Powder Conveying Systems

We, Candour Machinery Pvt. Ltd. Where Technology combines with engineering brilliance to give the cutting edge to the Plastic Processing equipments.

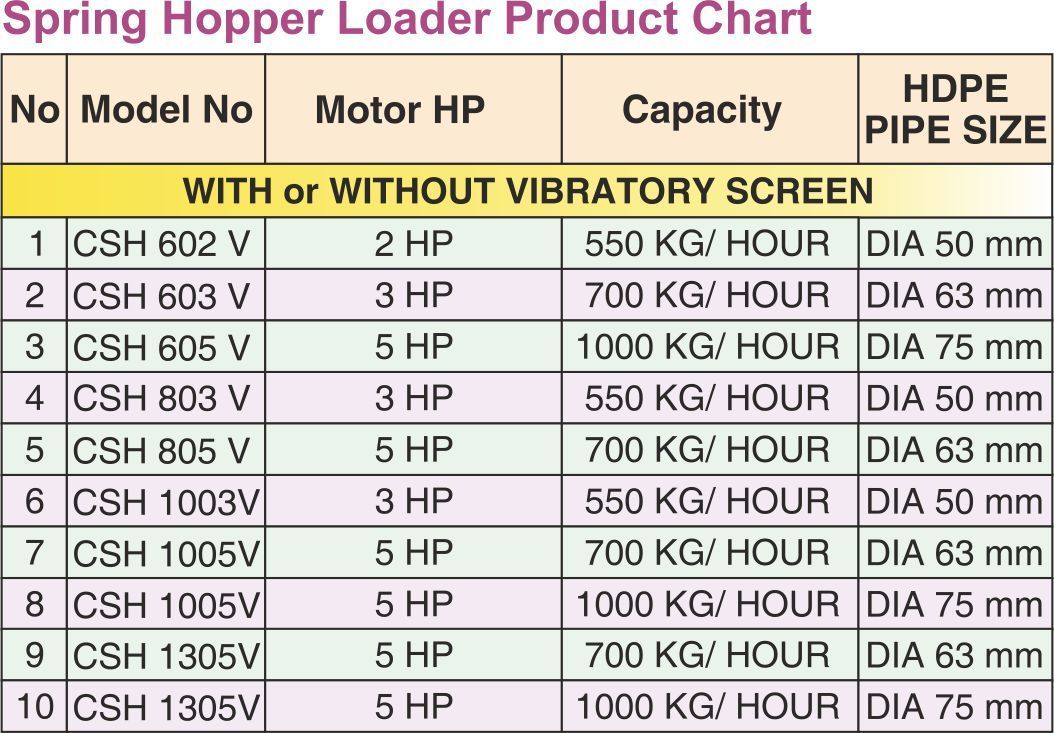

We believe that the solution arise from within the problem, hence one users friendly and cost effective solution to your entire conveying system. Since each product is unique in its own way, Candour Machinery designs & customizes special powder conveying spring hopper loader to suit your particular need. The hopper loader are used for conveying powder to main hopper of Extruder with length of 6 to 12 meter. Our hopper load are used by top name in the industry who prefer nothing but the best.

WE ARE OEM SUPPLIERS TO WINDSOR MACHINES LTD, RAJOO ENGINEERS LTD, ROLLEPAAL ENGINEERING INDIA PVT LTD, THETSOHN EXTRUSION TECHNIK AND SO MANY OTHERS.

Technical Specification:

- Machine of clear construction with easy access for operation and maintenance.

-

- Material Flow through Flexible HDPE Pipe and spring made from Special Spring Steel Material.

- Our All Spring Hopper Loader is equipped with Vibrating Fork in place of Rubber Diaphragm /Proximity.

- This Vibrating fork is maintenance free and proven the best as level switch for all Material application.

- Vibrating Screen with Vibrator Motor is on the top of Main Inlet Hopper. Also DOL starter of BCH Make is provided for Vibratory Motor.

- All Electrical parts are of standard make like BCH, L & T, Schneider electric.

- Timer to adjust delay time for material flow.

- Manual or automatic operation option.

- Various sizes like 13 / 10 / 8 / 6 meter are available as per customer requirement.

- All the paint is PU paint for better life of Unit.

- Operating Manual for Hopper Loader, Electrical Circuit Diagram, and Operating Manual.For Vibrating Fork is standard supply with Hopper Loader.

Optimized Performance

This powder conveying system offers a capacity range from 200 to 500 kg per hour, ensuring smooth and reliable material flow for various applications. Its screw conveying mechanism maintains gentle handling, suitable for sensitive powders, granules, and other industrial materials.

Durability and Efficiency

Built from robust stainless steel, this equipment guarantees long-lasting performance with minimal maintenance. The electric motor drives and PLC-based controls deliver precise, automated operation, making it an efficient solution for high-demand environments.

Versatile Applications

Engineered for food, chemical, and industrial sectors, the system accommodates a broad spectrum of powders and granules. Its compact dimensions and customizable discharge height up to 2 meters make it suitable for existing production layouts, maximizing space utility.

FAQs of Powder Conveying Systems:

Q: How does the screw conveying mechanism in this system enhance powder transfer efficiency?

A: The screw conveying mechanism ensures a uniform and controlled movement of powders, granules, or chemicals within the system, reducing the chance of clogging and minimizing product loss. This design maintains consistent flow rates and is effective for handling both fine powders and granules.Q: What types of powders and materials can be processed with this conveying system?

A: This system is suitable for a variety of materials including granules, fine powders, chemicals, and food products. Its versatility makes it an ideal choice for industries such as food processing, chemical manufacturing, and pharmaceuticals.Q: When is installation service available for this powder conveying system and what does it include?

A: Installation service is available upon purchase and can be scheduled for weekdays or as per client requirements. The service includes assembly, setup, alignment, and commissioning of the conveying system by trained technicians to ensure optimal performance.Q: Where can this system be installed within a production facility?

A: The compact dimensions (2650 x 960 x 1300 mm) and up to 2 meters discharge height allow for flexible placement within a manufacturing or processing layout. It fits well in both new and existing facilities, accommodating a range of production environments.Q: What is the maintenance process and frequency for this low-maintenance design?

A: Thanks to its sturdy stainless steel structure and quality engineering, routine inspection and occasional cleaning are typically sufficient. Lubrication of moving parts as per manufacturers recommendation helps ensure continued low-maintenance operation.Q: How does the PLC-based control system benefit powder conveying operations?

A: The PLC-based control system provides automated and precise management of operational parameters, allowing users to program and adjust settings easily. This increases reliability, safety, and consistency during powder handling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS